In an age where the global pharmaceutical industry is expanding and becoming increasingly complex, ensuring the safety and integrity of the drug supply chain has become a paramount concern. To address these concerns, the Drug Supply Chain Security Act (DCSA) was enacted, aiming to enhance the security and traceability of prescription drugs across the United States. This article delves into the key aspects of the DCSA, its implementation, benefits, and the preparedness required from drug manufacturers and pharmacists.

The November 2023 compliance deadline is rapidly approaching, so now is the time to take action to ensure your compliance.

1. What is the Drug Supply Chain Security Act, or DCSA?

The Drug Supply Chain Security Act (DCSA) is a piece of legislation signed into law by the United States Congress in 2013 as part of the Drug Quality and Security Act. The primary objective of the DCSA is to establish a comprehensive system for tracing and verifying the authenticity of prescription drugs as they move through the supply chain, from manufacturers to patients.

2. Why is the DCSA being implemented?

The implementation of the DCSA is a response to the growing threat of counterfeit, adulterated, and stolen pharmaceutical products infiltrating the legitimate drug supply chain. These illicit activities not only jeopardize patient safety but also undermine the integrity of the pharmaceutical industry. By implementing the DCSA, the government aims to ensure that patients receive safe and effective medications while maintaining the credibility of the pharmaceutical supply chain.

3. When is the DCSA being implemented, and who is affected by it?

The DCSA implementation occurred in phases, with full compliance expected by 2023. The act impacts all entities involved in the distribution of prescription drugs, including manufacturers, wholesalers, repackagers, and dispensers. This encompasses a wide range of stakeholders, from large pharmaceutical corporations to local pharmacies, all of whom must adhere to the new regulations to maintain compliance.

4. What are the five top benefits of the Drug Supply Chain Security Act (DCSA)?

Enhanced Patient Safety

The DCSA’s robust traceability system allows for rapid identification and mitigation of potentially unsafe or counterfeit drugs, minimizing the risks to patient health.

Improved Supply Chain Traceability

The act mandates the use of unique identifiers and barcodes, enabling stakeholders to track products at every step of the supply chain, reducing the likelihood of diversion or counterfeit products entering the market.

Efficient Recalls

In the event of a product recall, the DCSA facilitates swift and accurate identification of affected lots, helping manufacturers and distributors remove potentially harmful products from circulation more effectively.

Reduced Counterfeit Drugs

The DCSA’s stringent requirements make it harder for counterfeiters to infiltrate the supply chain, thereby protecting both patients and the industry from the detrimental effects of counterfeit drugs.

Preservation of Industry Integrity

By establishing a transparent and secure supply chain, the DCSA maintains consumer trust in pharmaceutical products and the businesses that produce and distribute them.

5. What do Drug Manufacturers and Pharmacists need to do to comply with the DCSA?

Both drug manufacturers and pharmacists play pivotal roles in ensuring compliance with the DCSA. Manufacturers are required to affix product identifiers, such as serial numbers and barcodes, on individual drug packages. They must also provide transaction information, history, and statements to wholesale distributors, ensuring the traceability of products.

Pharmacists, on the other hand, need to verify the legitimacy of drug products before dispensing them to patients. They should be well-versed in handling serialized drug packages and understanding the transaction history associated with the products they dispense. Training and education are crucial for pharmacists to seamlessly integrate DCSA requirements into their daily operations.

6. How can CSSI help with DCSA compliance?

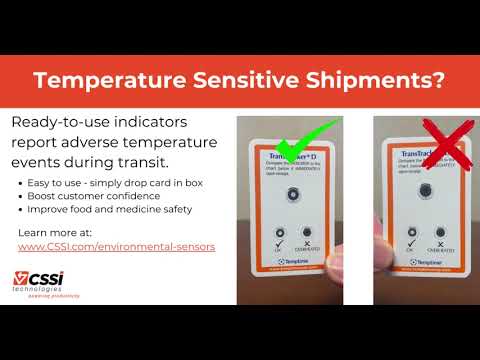

DCSA compliance will require both manufacturers and pharmacies to have reliable, quality barcode scanners or RFID readers on hand. CSSI is the leading source for scanner guns and RFID systems from top manufacturers such as Zebra Technologies. Not just a source for equipment, CSSI can assist you in configuring, deploying, and maintaining these devices throughout their lifecycle.

CSSI can also provide quality barcode label printers and label stock to enable on-demand printing of product labels.

Conclusion

In conclusion, the Drug Supply Chain Security Act represents a significant stride towards safeguarding the pharmaceutical supply chain and patient well-being. By mandating stricter traceability and accountability measures, the DCSA brings numerous benefits, from heightened patient safety to industry-wide integrity. Manufacturers and pharmacists must proactively familiarize themselves with the requirements of the act to ensure a seamless transition to a more secure and trustworthy drug supply chain. As the DCSA continues to roll out, its positive impacts on patient health and the pharmaceutical industry’s reputation are poised to be realized.

Contact CSSI for DCSA compliance help

To discuss your needs for Drug Supply Chain Security Act compliance, please contact CSSI