Autonomous Mobile Robots Drive Operations Productivity

In these days of labor shortages and rising expenses, warehouses and fulfillment centers are seeking technologies which can address these problems as well as the challenge of rising operating volumes. The Autonomous Mobile Robot (AMR), or warehouse robot, is the perfect technology to address supply chain pain points. Warehouse automation augments your human staff, enabling them to focus on higher-value activities, and reducing the amount of manned travel in your facility.

So what is an Autonomous Mobile Robot? Autonomous Mobile Robots are freely operating material handling devices which can be quickly trained to perform a broad variety of material movement tasks. The AMR uses a sophisticated mix of sensors and cameras to ‘see’, and powerful obstacle detection artificial intelligence enables it to safely operate independent of human guidance. The AMR’s action can be triggered by user input (a barcode, button press, or RFID signal), and will proceed to perform the task as directed. Examples of tasks for warehouse robotics might include pallet movement, warehouse case or rack movement, support for human workers in picking and order fulfillment, material handling, ‘virtual conveyor belt’ functionality, or removal of trash/recycling.

How Do AMRs Differ from AGVs?

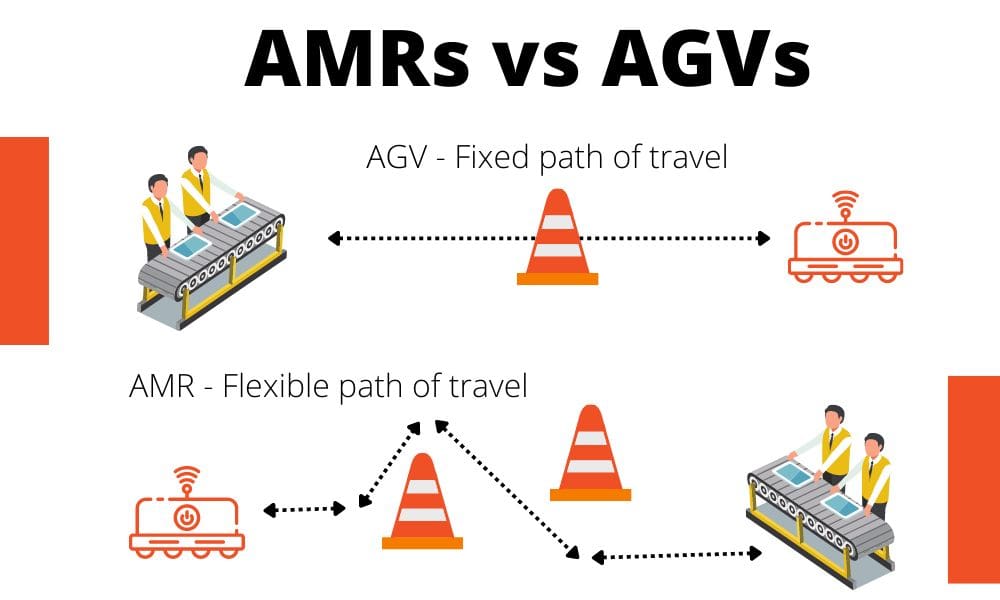

An Autonomous Robot navigates its way through your facility using a mix of sensors and cameras. This is different than the older Automated Guided Vehicle (AGV), which travels along pre-defined routes typically demarked by wires, magnetic strips, or sensors. Autonomous Guided Vehicles can be effective, but they are less ‘smart’. AGVs take more effort to setup because of the infrastructure requirements, which also means that they are less flexible and versatile – changing functions or routes can mean remarking the facility to accommodate.

Autonomous Mobile Robots, on the other hand, do not require wires or magnetic strips to be installed in the facility. Truly autonomous, the AMR provides flexible industrial automation of critical supply chain workflows. If its preferred path is blocked by obstacles, the AMR can find a new path. Also, AMRs can quickly be assigned new tasks and routes without modifications to the physical infrastructure of the plant. AMRs will also meet safety requirements – they are able to safely work alongside people, maintaining a situational awareness which enables the robots to avoid hazards.

When To Consider Autonomous Mobile Robots

The Autonomous Mobile Robot market is growing very fast as companies seek gains through warehouse automation. AMR deployments aren’t the solution in every case, but they can be extremely impactful in situations where:

- Labor shortages and rising costs for material handling are concerning to you

- You have frequently repeated movements of items or materials

- The beginning and ending locations for the material movement is well defined

- Your people lose meaningful amounts of time by transporting items around your facility

- You are burdened with a stationery and inflexible conveyor system, and would prefer flexibility

Consult With CSSI On Autonomous Mobile Robots

The Pennsylvania-based team at CSSI is available to discuss your challenges and potential use cases for industrial mobile robots. Please contact us to discuss an AMR solution today.