Have you considered wearable scanners for your warehouse? Many companies have discovered the benefits that a wearable barcode scanner or mobile computer can add in a warehouse environment, enhancing efficiency, picking accuracy, and safety. Wearable technology and mobile barcode printers can be a productivity game-changer for fast-paced warehouse operations!

Key Benefits of Wearable Scanners in Warehouse Operations

- Hands-Free Operation: Wearable scanners allow workers to keep their hands free while performing tasks such as picking, packing, and inventory management. This hands-free operation increases productivity as workers can handle items more efficiently without having to constantly pick up and put down a handheld scanner. Saving a few seconds per scan operation adds up to significant time savings in the course of a busy day!

- Increased Efficiency: With wearable scanners, workers can scan items more quickly and accurately. They can simply point the scanner at the barcode or QR code without needing to align a handheld scanner with the barcode. This streamlined process speeds up operations such as inventory management, order picking, and shipping/receiving.

- Real-Time Data Capture: Wearable scanners enable real-time data capture, providing immediate visibility into inventory levels, order status, and warehouse operations. This real-time data allows managers to make informed decisions quickly, optimize workflows, and respond promptly to changes in demand or supply chain disruptions.

- Reduced Errors: Wearable scanners help minimize errors in inventory management and order fulfillment. By eliminating manual data entry and reducing the risk of misreads or missed scans, wearable scanners improve accuracy and reduce the likelihood of shipping errors, stockouts, and overstock situations.

- Improved Ergonomics and Comfort: Unlike handheld scanners, which can be cumbersome and lead to repetitive strain injuries with prolonged use, wearable scanners are designed to be lightweight and ergonomic. They are typically worn as a back-of-hand scanner, ring scanner, or on a pendant. This ergonomic design enhances worker comfort and reduces fatigue during long shifts.

- Integration with Warehouse Management Systems (WMS): Wearable scanners can be seamlessly integrated with WMS and other enterprise systems, allowing for automated data capture and real-time synchronization of inventory and order information. Integration with WMS enables better tracking of inventory movements, improves order accuracy, and facilitates efficient replenishment processes.

- Enhanced Safety and Compliance: Wearable scanners can incorporate features such as voice commands, augmented reality (AR) guidance, and proximity sensors to enhance worker safety and compliance with warehouse protocols. For example, AR-enabled smart glasses can provide hands-free navigation instructions and safety alerts, reducing the risk of accidents and injuries in the warehouse environment.

Wearable Scanners for the Warehouse Keep Getting Better

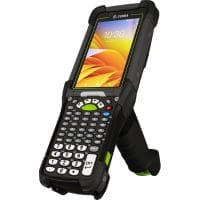

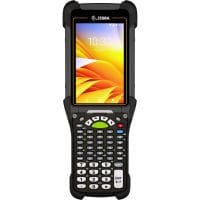

There was a time several years ago when wearable ring scanner options were not optimal. The highest-quality solutions were prohibitively expensive, form factors were not ideal, scanners were inflexible, and battery life was poor. However, times have changed. Today, CSSI can offer multiple wearable scanners which boast long batter life, powerful scanners, and easy-to-use form factors which make it a breeze to outfit the warehouse team. The typical warehouse worker appreciates these work-simplifying products, which further assures great adoption rates. Today, wearable tech can include products that function as a barcode reader, mobile computer, and even as a mobile printer.

How To Get Started With Wearables for Your Warehouse

Wearable tech offers numerous benefits in a warehouse environment, including hands-free operation, increased efficiency, real-time data capture, reduced errors, improved ergonomics, seamless integration with WMS, and enhanced safety and compliance. By leveraging wearable scanners, warehouses can optimize their operations, improve productivity, and maintain a competitive edge in today’s fast-paced logistics industry.

The best way to explore wearable scanners for the warehouse operation is to schedule a conversation with the team at CSSI. Our consultants can make recommendations based on your workflows and usage environment. Please contact us to get started with wearable scanners.