There is a large disparity in the perception of food safety between food industry professionals and consumers. CSSI’s partner Zebra Technologies has produced a data rich white paper which is a must-read for food industry professionals. The 2020 Zebra Food Safety Supply Chain Vision Study is based on surveys with almost 5,000 consumers and 462 industry executives.

2020 Zebra Food Safety Supply Chain Vision Study Download

Are you optimally employing cold chain technologies which ensure food supply traceability? This study will provide insights to guide you. The vision study is packed with useful information which will help provide insights for any food industry supplier.

Some insights from the report include:

Metrics around food safety and consumer trust

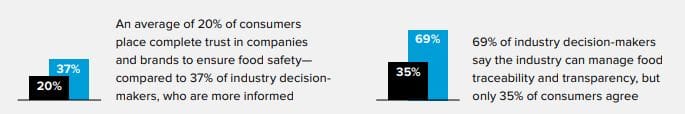

Zebra spoke with 4,957 consumers and 462 food producers and supply chain pros. Survey metrics bear out the realization that there is a disconnect in food safety confidence between food producers and the average consumer.

69% of industry decision makers believe the industry can manage food traceability and transparency… but only 35% of consumers agree!

Consumers have low faith in food safety

Food producers are under great pressure to improve speed and efficiency, all while maintaining strict food safety standards and addressing food safety issues which can result from a lack of preventive control. For example, frozen foods must be maintained at acceptable temperatures throughout the global supply chain.

Top 5 Food Safety Concerns

- Hygiene of restaurant kitchen staff

- Foodborne outbreaks

- Illness from contaminated food

- Recalls of food and beverages

- Hygiene of restaurant wait staff

What are the business consequences of food safety incidents?

Outbreaks of foodborne illness borne from poor food hygiene, food fraud, and contamination can give the entire industry a black eye. The consequences can be financial, reputational, legal, regulatory, and even co-operative if bad actors are shunned. Supply chain transparency and cold chain food traceability can help to improve confidence and reduce food safety incidents.

Confronting the food information challenge

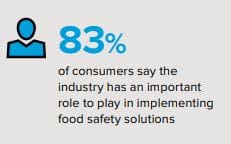

In general, consumer want to know where their food comes from, and a majority feel the industry is not sufficiently transparent about food quality. They expect the food safety professional to play a role in ensuring regulatory compliance in food facilities.

Key technology enablers to build consumer trust in food safety

Thankfully, technologies supported by companies like CSSI exist to address these food chain issues. Areas of benefit include:

- Reduce risk through proper handling, transportation, and storage

- Tracking of product perishability

- Food supply chain optimization

- Regulatory compliance with food safety guidelines

- Intake management of raw material and ingredients

- Greater transparency in the food supply chain and cold chain

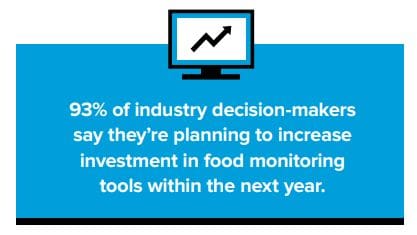

Traceability technology investment

Technologies such as barcoding, RFID, freezer grade mobile computers, and software solutions play a role in addressing traceability, food safety, and regulatory compliance. As an example, consider the Zebra MC9300, a rugged freezer-grade handheld suitable for cold storage and challenging food production environments. Food safety risk can be diminished with confidence if a food manufacturer invests in technologies such as these, after consulting with an experienced integrator such as CSSI. 62% of food processing pros and supply chain partners expect to operate more predictively over the next 5 years — 62% increase from today!

Regional findings within the study

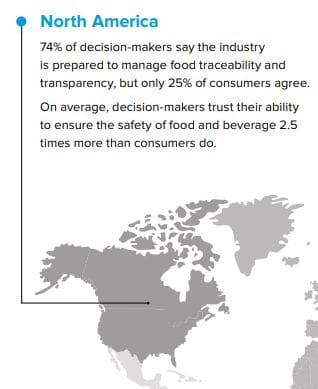

This is a global study, with findings from all continents. In North America, the typical food manufacturer or food safety professional trusts food production safety 2.5 times more than the average consumer!

The trust gap: information is power!

With sufficient visibility and access to information, it is possible to improve perceptions and results around the food value chain, while reducing food safety incidents!

How can CSSI Technologies help?

CSSI’s experienced team of integrators can support food producers, freezer warehouses, and cold chain participants in improving operational results. Contact us today to discuss your unique situation.