All about direct marking and how to scan DPM marks

In today’s industrial and manufacturing landscape, there is a continually growing need for reliable identification and traceability of components and products. Direct Part Marking (DPM) has emerged as a critical technology for achieving these goals, offering durable marking solutions that enhance efficiency and enable seamless tracking throughout the product lifecycle.

What is DPM (Direct Part Marking)?

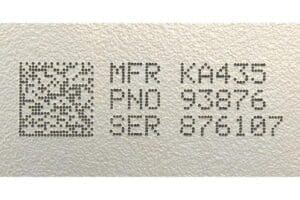

Direct Part Marking refers to the process of using a marking system for permanently marking a part or component with a unique identifier directly on its surface. Unlike traditional barcode labels or RFID tags, DPM involves using direct marking machines for marking methods such as dot peen that engrave, etch, laser, or otherwise inscribe information directly onto the part itself. Common direct marking techniques include laser marking, dot peening, laser engraving, chemical etching, and inkjet printing designed for durability and readability under various conditions. These DPM marks can be read by special scanners, similar to barcode scanning.

Why is DPM used instead of typical barcodes?

Direct Part Marking offers several advantages over traditional barcode labels:

- Durability: DPM marks are resistant to wear, abrasion, and an abusive harsh environment, ensuring permanent identification.

- Space Constraints: In applications where space is limited or where labels may not adhere well, DPM provides a small yet permanent marking solution.

- Traceability: A direct part mark enables reliable part identification throughout the product lifecycle, supporting quality control, maintenance, and regulatory compliance.

In short, a bar code applied with an adhesive label may not be a durable choice for very small parts and/or items which are subject to wear and tear. Direct marking is a more permanent solution which also has the advantage of being readable at a very small size.

Industries and Applications where Direct Part Marking is utilized

Direct marking (also known as laser marking technology or dot peen marking) finds extensive use across diverse industries where traceability, safety, and quality assurance are critical:

- Automotive: Used for automotive part identification, traceability in assembly processes, and counterfeit prevention.

- Aerospace: Ensures compliance with stringent safety regulations, facilitates maintenance and component tracking.

- Medical Devices: Supports tracking of components for quality control, recalls, and regulatory compliance.

- Electronics: Enables tracking of components and products through manufacturing and distribution processes.

- Defense: Essential for parts identification, maintenance tracking, and ensuring supply chain security.

- Consumer Goods: Used in anti-counterfeiting measures and for tracking products through distribution channels.

Special considerations for scanning technology to read DPM marks

DPM marks can’t be read with a typical barcode scanner. Reading a direct part mark requires specialized barcode reader technologies capable of interpreting marks that may vary in depth, material, and surface finish. Key considerations for this type of marking method include:

- Imaging Technology: Scanners equipped with high-resolution cameras or sensors capable of capturing fine details and contrast differences in marked surfaces.

- Lighting: Adequate lighting is crucial for enhancing contrast and visibility of marks, especially on reflective or uneven surfaces.

- Software Algorithms: Advanced decoding algorithms designed to interpret marks that may be distorted or partially obscured due to surface irregularities.

- Verification Standards: Compliance with ISO standards (like ISO 15415 for 2D barcode symbols) ensures that scanners can reliably read and verify DPM marks.

Specialized Scanners for Capturing DPM Marks

CSSI is a specialist in data capture technologies such as barcodes, RFID, and direct part marking. We have available a number of solutions capable of scanning a DPM barcode or symbol. The right solution will depend on your particular needs – we can work with you to select the right product. Several of the available DPM scanning options include:

Contact CSSI For DPM Scanning Options

Direct Part Marking (DPM) plays a pivotal role in modern manufacturing and industrial processes, offering durable and reliable identification solutions that enhance traceability, quality control, and regulatory compliance across various sectors. Contact CSSI to discuss your DPM application and barcode scanner applications, and we will help you select and test a DPM code capture product to meet your requirements.